Today we will discuss about battery ignition system main

parts, function, working, advantages and Disadvantages. Most of SI engine used

battery ignition system. In this system a 6 volt or 12 volt battery used to

produce spark. Passenger cars, light truck, motorcycles and large stationary

engines are fitted with this system.

Battery ignition system:

Main Parts of battery ignition system:

Battery

A battery is used to provide energy for ignition. It is work as storage of

energy and charged by dynamo, which is driven by engine. It converts chemical

energy to electric energy. Two types of battery used in spark ignition system,

lead acid battery and alkaline battery. The first one is used in light duty

commercial vehicle and the other one is used in heavy duty commercial vehicle.

It is housed in primary side of ignition coil.

Ignition switch

It is used to turn on and off the ignition system. Battery is connected to the

primary winding of ignition coil by ignition switch and ballast resistor.

Ballast resistor

It is connected in series with primary winding to regulate current in primary

winding. It is used to prevent injury due to overheating of ignition coil. It controls

the current passes through primary winding. It is made by iron. Iron has property

of increase electrical resistance rapidly by increase in temperature at certain

limit. This additional resistance resists flowing current which control the

temperature of ignition coil.

Ignition coil

Ignition coil is the main body of battery ignition system. The purpose of

ignition coil to step up the battery voltage (6 or 12) to a high voltage, which

is sufficient to produce spark at spark plug. It consist a magnetic core or

soft wire or sheet, and two electrical winding called primary winding and

secondary winding. The primary winding has generally 200-300 turn and the end

are connected to exterior terminal. The secondary has almost 21000 turns of

copper wire which is insulated to withstand with high voltage. It is located

inside the primary winding and its one end connected to secondary winding and

other end is grounded either to primary winding or to the metal case. This

entire unit is enclosed in a metal container which makes it a compact unit.

Contact breaker

This is a mechanical device making and braking the primary circuit to ignition

coil. When the points are closed current flow in ignition coil and when it

open, flow of current stopped.

Capacitor

It is a simple electrical capacitor in which two metal plate are separated by

an insulating material with a distance. Commonly air is used as insulating

material but for particular technical requirement some high quality insulating

material is used.

Distributor

Distributor is used in multi cylinder engine to regulate spark in each spark

plug at correct sequence. It distribute ignition surge in individual spark plug

in correct sequence. There are two types of distributor. One is known as carbon

brush type and the other one is gap type. In carbon brush type carbon brush

carried by the rotor arm sliding over the metallic segment embedded into the

distributor cap or molded insulating material. This makes electric connection

or secondary winding with spark plug. In gap type distributor electrode of

rotor arm pass close to but does not make contact with the distributor cap. So

there is no wear of electrode.

Spark Plug

A spark plug generally has two electrodes which are separated with each other.

A high potential discharge flow through it which generate spark and ignite the

combustion mixture in cylinder. It mainly consist two electrodes a steel shell

and an insulator. The central electrode connected with the supply of ignition

coil. It is well insulated with the outer steel shell which is grounded. There

is a small air gap between steel shell and central electrode, between which

spark is generated. The electrode usually made by high nickel alloy so it can

withstand with high temperature and corrosion resistance.

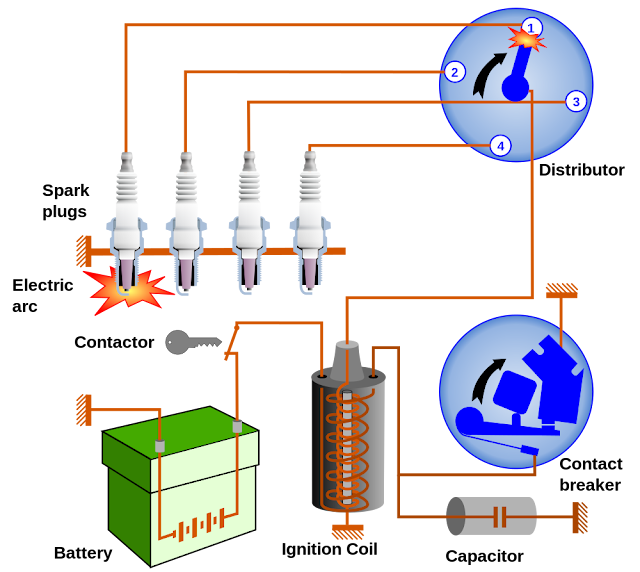

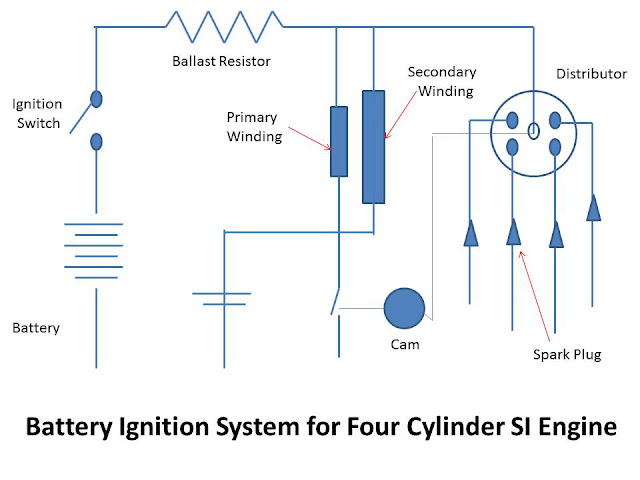

Working of Battery Ignition System:

In the battery ignition system ignition coil stores the

energy in form of magnetic field and deliver it at the instant of ignition, in

form of high voltage current with high tension wire to correct spark plug. The

diagram of four cylinder battery ignition system is as follow.

- First low voltage current flow form battery to the primary coil through ignition switch and ballast resistor.

- Ballast resistor regulates the temperature of ignition coil by regulating current passing form it.

- The ignition capacitor connected in parallel with contact breaker. One end of secondary winding is also grounded through contact breaker.

- When the ignition switch is closed, the primary winding of the coil is connected to the positive terminal, and current flow through it known as primary current.

- The current flows form primary coil produces a magnetic field which induces an EMF in secondary coil.

- The cam regulate the contact breaker. Wherever the breaker open, current flows into condenser, which charged the condenser.

- As the condenser become charger the primary current falls and the magnetic field collapses. This will induces a much higher voltage in condenser.

- Now the condenser discharge into the battery which reverse the direction of both primary current and magnetic field. This will induce a very high EMF in secondary winding.

- Now this high voltage EMF produce spark at correct spark plug through distributor.

Advantages and Disadvantages:

Advantages:

1. At the time of starting or at low speed good spark is available.

2. The battery which is used to generate spark can be used to

light other auxiliary like headlight, tell light etc.

3. Initial expenditure is less and

it has low maintenance cost.

4. Ignition system is not affected by

adjusting spark timing in battery ignition system.

Disadvantages:

1. Time available of built up the current and stored energy is

decrease as speed of engine increases.

2. Contact breaker subjected to both electrical and mechanical

wear which results short maintenance interval.

3. The primary voltage decreases as the engine speed increase.

So it is not fully reliable of high speed engine.

It is all about battery ignition system parts, principle,

working, advantages and disadvantages. If you have any query regarding this

article, ask by commenting. If you like this article doesn’t forget to share it

on social networks.