Today I am

going to tell you about what is rivet and types of rivets. We know that in a machine

or in a structure, many small components are jointed together by some of mean.

The design of joints is as well as important like machine because any loose

joint may cause of failure during operation. In the

mechanical, there are two types of joints, first one is permanent joint i.e.

welding, rivets. And the other one is non-permanent i.e. bolt.

A rivet is

a permanent mechanical joint which are broadly used to joint structure, ships,

barrels etc. These joints are widely used in ship and boiler industries to join

the structure member.

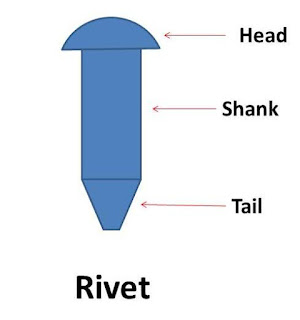

A rivet is a

mechanical joint which is cylindrical in shape and having a head. It is used to

joint structure member. It is a permanent joint which mean that it cannot be

disassembled without failure of machine component. This joint form interference

fit to joining the parts. Rivets apply mechanical force on the two plates which

joint the plates permanently.

The process

by which two plates are joints together by use of rivet is called riveting. In

this process mechanical force is applied to make the joint strong and leak

proof. In this operation two holes are created in both plates and the rivet is

inserted between these holes. At the other end a force is applied through a die

which deform the tail plastically and form a required shapes which hold the

rivet in the hole and apply a mechanical pressure force which joint the

structure. This process is shown by figure.

Types of Rivets:

Rivets are used as permanent fastener in mechanical industries. It is less costly and effective way of joining a structure. According to the requirement, rivets are available in many shapes and sizes.

According to the design of rivets, these are classified as follow.

Solid rivets:

Solid rivets used in many structure members such as in ships, Bridge

etc. but now days these rivets are almost replaced by welding and brazing.

According to head design these are as follow:

Round Head Rivet:

Countersunk Head Rivet:

Oval Countersunk Head rivet:

Blind Rivets:

Blind rivets are also known as hollow rivets. These rivets are used widely in aircraft industries, shipping industries and in many electronics industries. The main advantage of these rivets that they have the fastest rate of installation among all fasteners. One more benefit is that this can be install from the single side. A blind rivet is used when it is impossible to seen rivet tail.

For better understanding, watch the video.

Riveted Joints:

There are

two types of rivet joints.

1. Lap joint

When the

plates to be joint, are bring together which overlap each other at face, and

rivet inserted in overlap section as shown in figure, the joint is known as lap

joint.

According to

the number of rows of rivets and its arrangement, this joint is further

classified as follow

Single riveted lap joint:

In this joint, the rivets are inserted in the single line, that's why it is called as single riveted lap joint.

Double riveted lap joint:

In this joint, the rivets are inserted in the double line, that's why it is called as double riveted lap joint.

Chain riveted lap joint:

Zig-Zag riveted lap joint:

2. Butt joint:

In this type

of rivet joint both plates are bring together without overlap each other and

joint are made by use of one or two cover plate as shown in figure.

According to

cover plates, number of rows of rivets and arrangement, this joint is

classified as follow.

Single straps butt joint:

In this joints, there is only one cover plate used so it is known as single strap butt joint.

Double straps butt joint:

In this joint cover plates are used both side of the work piece, so it is known as double straps butt joint.

Single riveted butt joint:

Double riveted butt joint:

Chain riveted butt joint:

Zigzag riveted butt joint:

Today we have learnt about what is rivets and types of rivets. We have also learnt about types of rivet joints. If you have any query you can ask by commenting or