Today we will

discuss about belt drive and its types. We all know that belt drives are used

to transmit power form one shaft to another, which have not common axis. In the

fact belt drive is used to transmit power. One alternate of belt drive is gear

drive but gear drive is not economical when large distance between driving and

driven shaft. Belt drive is very popular in power transmission due to its lower cost and high performance. They are used in many industries. The main principle of belt drive is friction. The power transmission between shaft is depend on friction between belt and pulley.

The amount of power transmitted depends upon the following

factors :-

1. Velocity of belt

2. Tension under belt placed on pulleys

3. Arc of contact between thee belt and the smaller pulley

Factor consider while selecting belt drive:-

1. Speed of the driving and driven shaft

2. Speed reduction ratio

3. Power to be transmitted

4. Center distance between shafts

5. Shaft layout

Types of belt drives:-

According to power transmitted

1. Light drives:

These are used to transmit small power at belt speed up to

about 10m/s. It is usually used in agricultural machines and small machine tools.

2. Medium drives:

These are used to transmit medium power at belt speeds from

10m/s to 22m/s. It is used in machine tools.

3. Large drive:

These are used to transmit large power at belt speeds above

22 m/s. These are used in compressor, generator and heavy machinery.

According to the arrangement of belt:

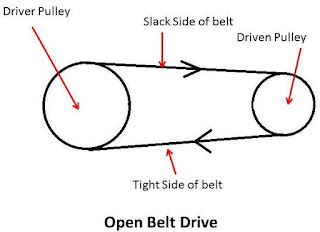

1. Open belt drive:

These belt drive used with shaft s arranged parallel and

rotating in same direction. In this drive the driver pulley pulls the belt from

one side and delivery it to the other side. Thus the power is transmitted form

driver pulley to driven pulley. The tension in the lower side of the belt is

more than the upper side. So the lower side is known as tight side and upper

side is known as slack side.

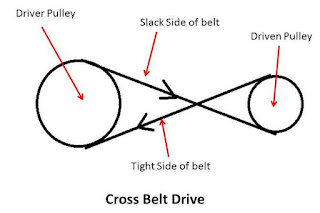

2. Crossed belt drive:

This belt drive is used when shafts are parallel to each

other but rotating in opposite direction. In this case the driver pulls the

belt form one side and delivers it the other side. In this drive tension is

more on that side where driver pulls the belt, so this side is known as tight

side and other is known as slack side.

3. Quarter turn belt drive:

This belt drive is also known as right angle belt drive. This

drive is used when shafts arranged at right angles and rotating in one definite

direction. To prevent the leaving the belt in this drive the width of face of

pulley is 1.4 times greater that the width of belt.

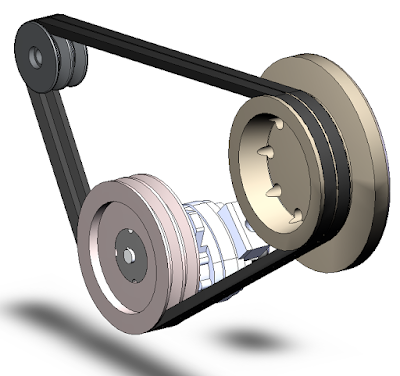

4. Compound belt drive:

A compound belt drive is used when power is transmitted on

more than one shaft. In this arrangement power is transmitted form one shaft to

another through a number of pulleys.

These all are main types of belt drives used in industries. If you have any query regarding this article ask by commenting.

These all are main types of belt drives used in industries. If you have any query regarding this article ask by commenting.